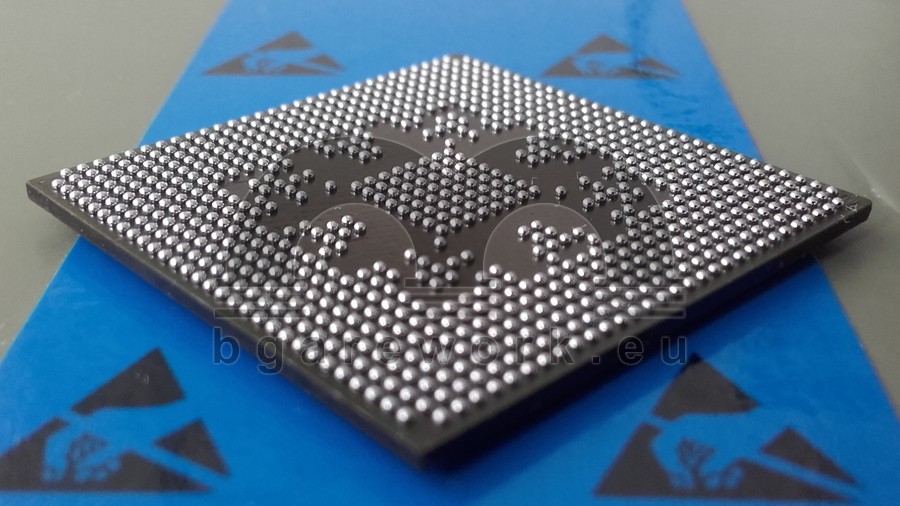

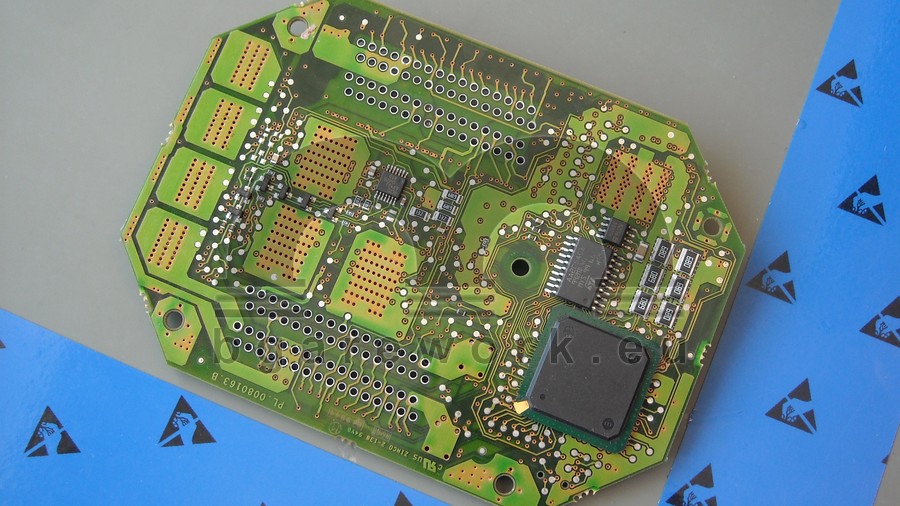

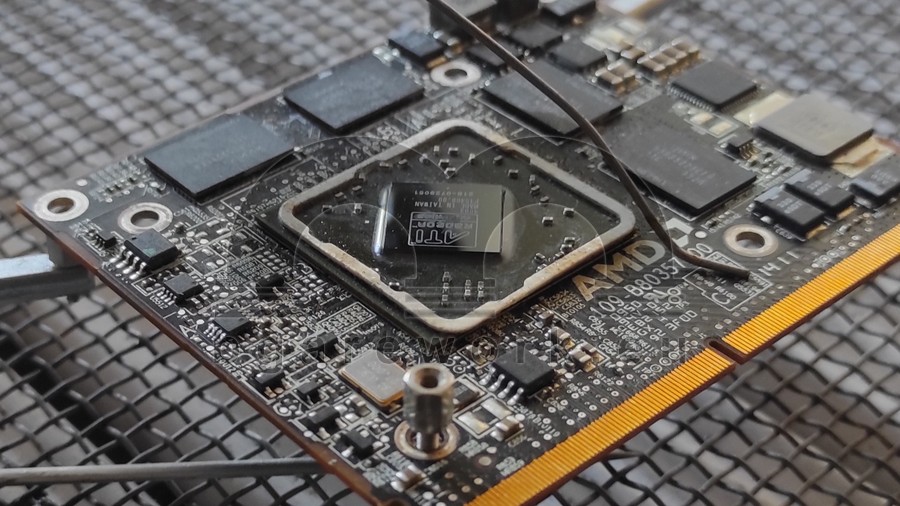

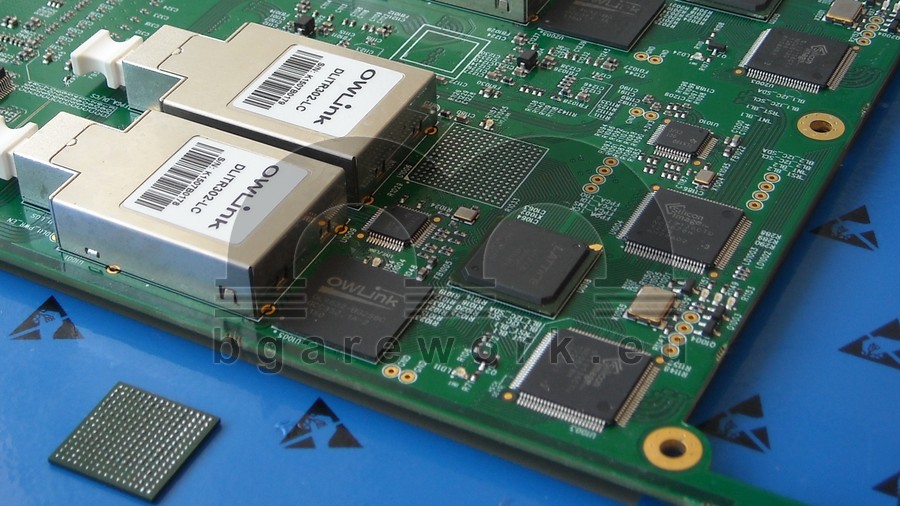

Our company focuses on BGA soldering, BGA replacement, BGA reballing, and BGA rework, as well as soldering QFN, QFP, CSP packaged components. We have vast experience working for various industries, among others, the arms industry, the car manufacturing industry, and the entertainment industry. We have soldered electronic components of submarines, military radars, car electronics.

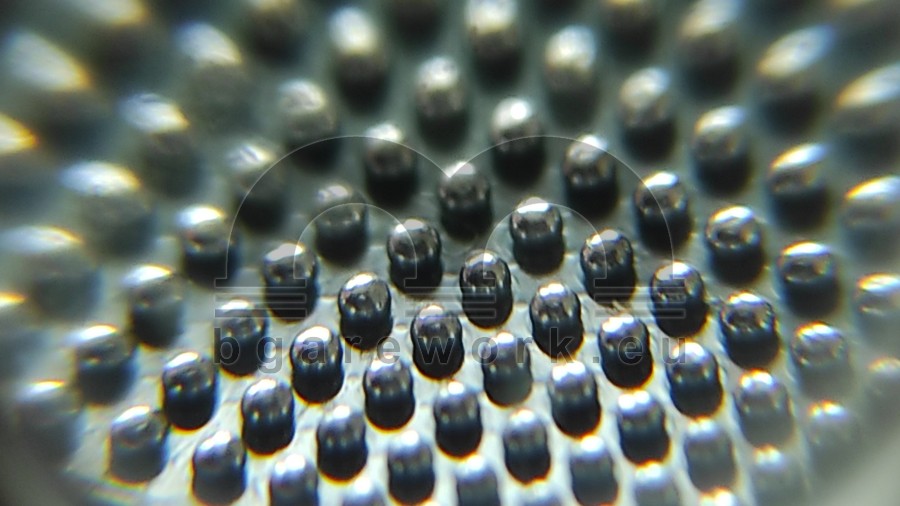

The foundation of our work lies on 3 things: The component’s dryness, and ESD work environment, and inspection of work quality with microscopes.

Drying

The premise for a successful BGA soldering is a dry, moisture-free component. It’s important to preheat, dry out the moisture from the component before soldering on it,

otherwise a humid, moist component could get humpy, damaged during soldering, have it’s lifespan shortened, and reduce it’s working temperature range.

ESD work environment

We abide by the ESD protection rules while working on electronics.

More info: www.bgaforrasztas.hu

Magnetron Bt

Székely László

IT engineer

2085 Pilisvörösvár Görgey street. 10.

- Tel. +36309430972

- OTP: 11703006-20366429

- Cg.: 13-06013810

- Pestmegye, 1992.09.28.

- IBAN : HU98 1170 3006 2036 6429 0000 0000

- OTP Bank BIC (SWIFT) code: OTPVHUHB

- MwSt-Nummer/VAT Number: HU 24476795